Choosing the Right Vacuum Pump: Tips and Considerations

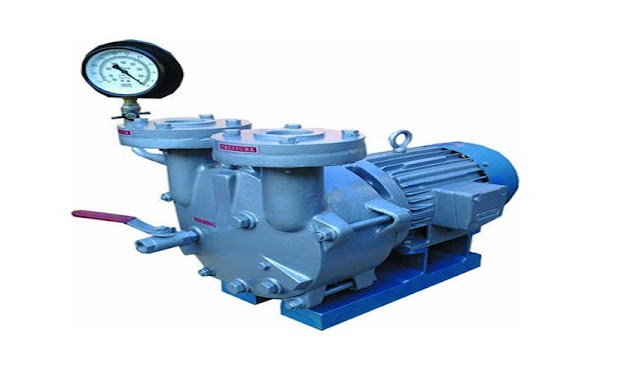

Vacuum pumps play a vital role in various industries, from manufacturing and research to healthcare and automotive. They're essential for creating vacuum environments necessary for processes like material handling, degassing, and vacuum sealing.

However, selecting the right vacuum pump for your specific application can be a daunting task, given the multitude of options available in the market. To help you make an informed decision, let's explore some tips and considerations when choosing a vacuum pump.

Understand Your Application

The first step in selecting the right vacuum pump is understanding your application requirements thoroughly. Consider factors such as the desired vacuum level, flow rate, gas composition, and operating conditions. Different applications may require specific pump technologies to achieve optimal performance.

Types of Vacuum Pumps

Vacuum pumps Australia come in various types, each suited for different applications. Common types include rotary vane pumps, diaphragm pumps, scroll pumps, and turbomolecular pumps. Research the characteristics and capabilities of each type to determine which one aligns best with your application needs.

Vacuum Level Requirements

Vacuum levels vary depending on the application. Some processes require high vacuum levels, while others only need low or medium vacuum. Ensure the vacuum pump you choose can achieve and maintain the desired vacuum level consistently.

Flow Rate

Flow rate, measured in cubic meters per hour (m³/h) or liters per minute (L/min), is another critical consideration. It determines how quickly the vacuum pump can evacuate air or gas from the system. Select a pump with a flow rate suitable for your application's demands to ensure efficient operation.

Chemical Compatibility

Consider the compatibility of the vacuum pump with the gases or vapors present in your application. Certain pump materials may react with specific chemicals, leading to contamination or corrosion. Choose a pump constructed from materials resistant to the substances it will encounter.

Noise and Vibration Levels

Depending on where the vacuum pump will be installed, noise and vibration levels may be significant factors to consider. Some applications require quiet operation, while others can tolerate higher levels of noise. Look for pumps with noise and vibration reduction features if necessary.

Maintenance Requirements

Regular maintenance is essential for prolonging the life of your vacuum pump and ensuring optimal performance. Consider factors such as ease of maintenance, availability of spare parts, and serviceability when choosing a pump. Selecting a pump with minimal maintenance requirements can save time and money in the long run.

Energy Efficiency

Energy consumption is a significant operating cost for vacuum pumps Australia. Look for pumps with high energy efficiency ratings to minimise energy usage and reduce operating costs. Features such as variable speed drives and automatic shut-off mechanisms can help optimise energy consumption.

Footprint and Installation Requirements

Consider the physical footprint of the vacuum pump and whether it will fit into your existing space. Also, assess installation requirements such as power supply, ventilation, and any special mounting considerations. Choosing a pump that integrates seamlessly into your facility can simplify installation and operation.

1Budget Constraints

Finally, consider your budget constraints when selecting a vacuum pump. While it's essential to invest in a high-quality pump that meets your application requirements, be mindful of cost considerations. Evaluate the total cost of ownership, including initial purchase price, operating costs, and maintenance expenses, to make an informed decision.

Conclusion

Choosing the right vacuum pumps Australia requires careful consideration of various factors, including application requirements, vacuum level, flow rate, chemical compatibility, noise and vibration levels, maintenance requirements, energy efficiency, installation considerations, and budget constraints.

By thoroughly assessing these factors and selecting a pump that aligns with your specific needs, you can ensure optimal performance and efficiency in your vacuum processes. Remember to consult with knowledgeable experts or suppliers to help guide you through the selection process and ensure you make the best choice for your application.

Comments

Post a Comment